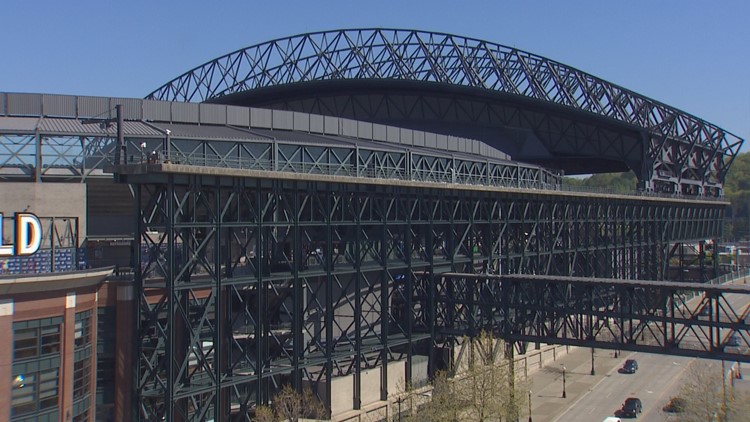

It covers nearly nine acres and has enough steel to build a 54-story building, and all of it moves.

Rob Wolford with Safeco Field Engineering says the stadium roof is doing well as it enters its 17th year, but it also receives annual inspections from outside engineers and regular maintenance.

"It's holding up. It's doing well," says Wolford. "We've done a lot of work up here."

The anemometer that measures winds at the top of the roof some 269 feet above field level is just one that keeps an eye on the weather. The roof can move below 30 miles per hour and is usually closed in wind storms to prevent any damage to the stadium below.

The roof rolls on 128 wheels, 96 of which are powered. The roof weighs 22 million pounds, which works out to be roughly to the same weight as more than 44 six-axle freight locomotives at nearly a half million pounds each.

And it's not just fans that pack the stadium during baseball season. Birds are frequent visitors to the roof, leaving leftovers behind. Bones, mussel shells, crab legs are cleaned out, and especially off the top of the rails, to keep motion as smooth as possible.

Crews are also up on the "runways" to double check the rails for debris, listen for sounds and look at places that the cameras don't see from the control booth.

One of the trickier parts about moving this massive roof is moving both sides in lock step, so the roof structure doesn't twist. That depends on what Wolford calls "resolvers" - precise measuring devices that ride along the rails and measure how far each side is moving.

"They give a specific number at each location as it rolls along. The resolver numbers change, and that tells the drives to speed up or slow down,” says Wolford.

If those speeds don't match within parameters, the system will stop the roof on its own.

How fast does it go? Wolford says there are three speeds. Fast opens the roof in 10 minutes. Normal opens it in 20. A maintenance speed moves along at five feet a minute to precisely position the roof when things need to be checked and repaired.

Perhaps most surprising is how often the roof is moved. Wolford says under the original plan, the thought was that it would move 25 to 30 times a year. In reality, it moves 300 to 500 times a year. Often, the movement is to help manage the environment for the grass inside the stadium, to control dew on some nights when there's an early game the next day, and provide plenty of sun during a nice day.